Dyeing

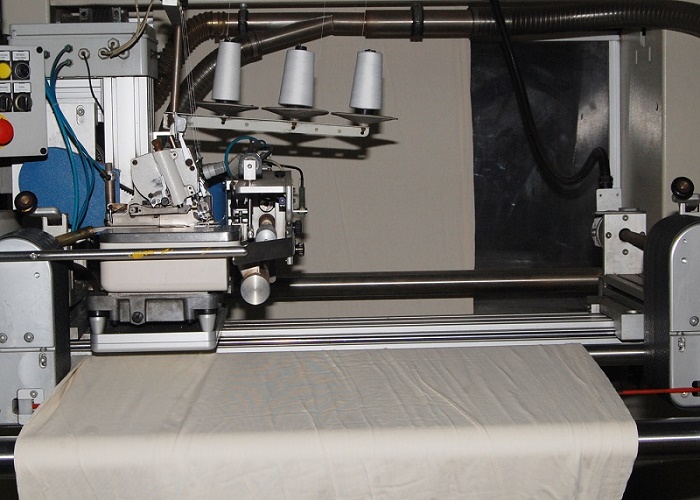

To achieve and maintain our high standards, we employ the most advanced techniques with the latest machinery available to the garment and fabric manufacturers. Our dyeing facility is equipped with a state-of-the-art lab, dyeing systems, and a variety of finishing machines that provide unique touches as per the client’s requirements. Our automated packaging line involves zero human intervention to ensure zero-handling of fabrics.